Vacuubrand MD 4C NT

Three-stage chemistry-design diaphragm pumps are an excellent solution for continuous, oil-free pumping of corrosive gases and vapors and meet even challenging requirements. The three-stage design provides the advantageous combination of high pumping speed and very low ultimate vacuum. All parts of the MD 4C NT in contact with pumped media are made of chemically resistant fluoroplastics. Well-proven PTFE sandwich diaphragms provide increased reliability and extended operating life. Due to the gas ballast valve and its very good ultimate vacuum (even with gas ballast) the MD 4C NT is also suitable for pumping condensable vapors of high-boiling solvents. The NT-series features further improved performance data, easy service and superior vapor tolerance. Three-stage chemistry diaphragm pumps are an excellent choice for applications with corrosive gases and vapors with high vacuum requirements. Typical applications are parallel and rotary evaporators, concentrators, drying ovens and many other laboratory applications. The MD 4C NT has an outstanding performance for pumping large amounts of vapor, e.g., out of drying ovens and gel dryers. This powerful 110v pump is at the heart of a complete family of well-proven and reliable vacuum systems and pumping units for larger lab applications.

Performance Features

- Outstanding chemical resistance and superior vapor tolerance

- Exceptionally high performance even at low vacuum

- Excellent ultimate vacuum even with gas ballast

- Whisper quiet and very low vibration

- Long diaphragm life, maintenance-free drive system

- Technical Data

|

MD 4C NT Specifications |

|

|

Max. Pumping Speed 50 Hz |

3.4 m3/h |

|

Max. Pumping Speed 60 Hz |

2.2 cfm |

|

Ultimate Vacuum |

1.5 mbar / 1.1 torr |

|

Ultimate Vacuum with Gas Ballast |

3 mbar / 2.2 torr |

|

Number Of Heads |

4 |

|

Number Of Stages |

3 |

|

Ambient Temperature (Operation) |

10°C to 40°C |

|

Ambient Temperature (Storage) |

-10°C to 60°C |

|

Max. Back Pressure (Abs.) |

1.1 bar |

|

Anschluss Saugseitig |

Hose Nozzle DN 8-10 mm |

|

Outlet Connection |

Hose Nozzle DN 8-10 mm |

|

Rated Motor Power |

0.25 kW |

|

Rated Motor Speed at 50/60 Hz |

1500/1800 min-1 |

|

Protection Class |

IP 40 |

|

Dimensions (L x W x H) |

328mm x 243mm x 198mm |

|

Weight |

14.3 kg |

|

Noise Level at 50 Hz, typ. |

45 dBA |

|

ATEX Conformity |

II 3/- G Ex h IIC T3 Gc X Internal Atm. Only |

|

NRTL Certification |

Yes |

|

Items Supplied |

Pump completely mounted, ready for use, with manual |

|

Rated Mains Voltage Range 1 |

230 V |

|

Mains Frequency 1 |

50-60 Hz |

-

MD 4C NT - Pumping Speed Graph at 50 Hz

-

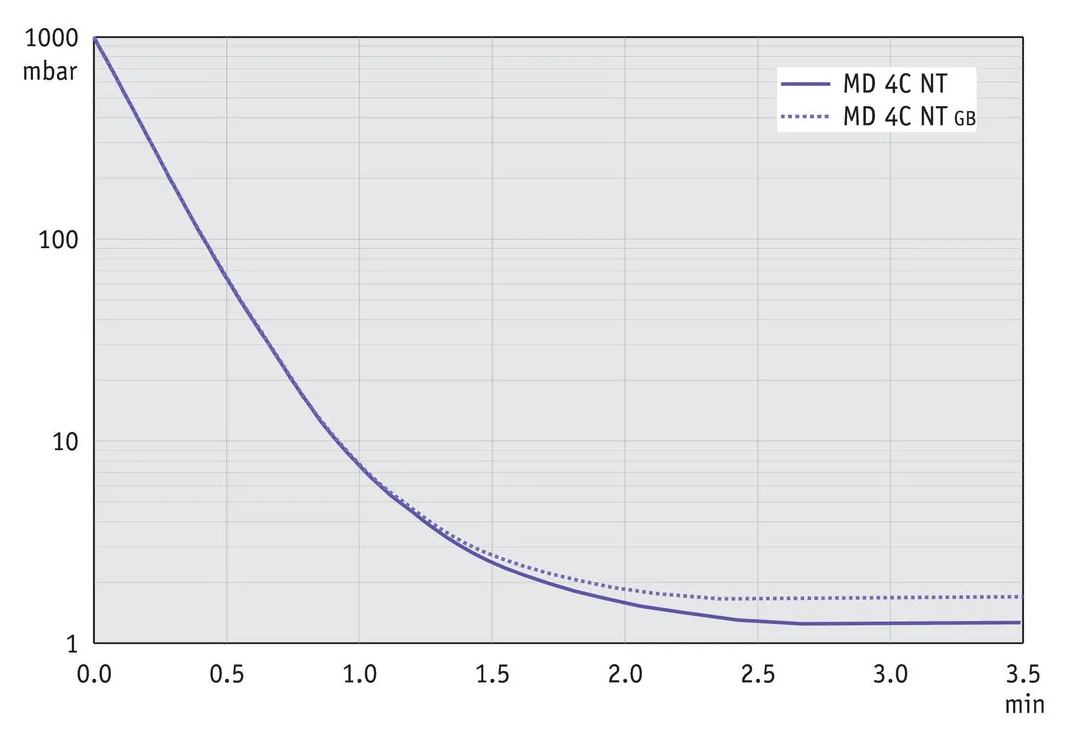

MD 4C NT - Pump Down Graph at 50 Hz (10L volume)

-

MD 4C NT - Pumping Speed Graph at 60 Hz

-

MD 4C NT - Pump Down Graph at 60 Hz (10L volume)

-

-Technical data are subject to change without notice-

MD 4C NT - Dimension Sheet

For Technical Support, Questions, or Other Issues Please Email or Call Us!

6. Warranty, Limitation of Liability

6.1 VACUUBRAND warrants that its delivered goods (including any agreed installation) are free of defects at time of risk transfer. The condition owed, durability, and use of the deliverables is based on the specification, product description, and/or operating instructions agreed upon.

6.2 Should the customer require the delivered goods for purposes other than those agreed, he must take responsibility himself for examining their special suitability for this - also in terms of product safety – and ensure their compliance with all relevant technical, legal or regulatory provisions before the intended use. VACUUBRAND excludes liability for any usability not confirmed by VACUUBRAND. In the case of material or design requirements of the customer, VACUUBRAND shall accept no liability for the suitability or permissibility of the desired materials or designs. Compliance with safety-related and occupational health regulations depends on the location and operating conditions of which VACUUBRAND has no prior knowledge. Action for ensuring compliance shall therefore be the responsibility of the customer or his buyer.

6.3 VACUUBRAND shall not be liable for the consequences of improper handling, use, maintenance and operation of the delivered goods; the consequences of normal wear and tear, in particular of wearing parts such as diaphragms, seals, valves, vanes, condensers, oil and the breakage of glass or ceramic parts; for the consequences of chemical, electrochemical or electrical influences; or non-observance of the operating instructions.

6.4 If a notice of defect is justified, VACUUBRAND shall initially only be required to provide cure. Any such cure shall be, at the discretion of VACUUBRAND, either rectification of the defect or delivery of goods free of defects. Further warranty claims shall only apply in the event of rejection, impossibility or failure of the cure.

6.5 The customer must, immediately upon receipt of the goods, inspect them carefully, also in terms of product safety, and notify obvious defects immediately in writing; any hidden defects must be immediately notified upon discovery. The customer must notify the carrier immediately of any transport damage. Failure to observe the testing and notification obligation shall void any customer claims for defects.

6.6 VACUUBRAND's liability for slight negligence shall be limited to claims for injury to life, limb or health, to claims under the Produkthaftungsgesetz (German Product Liability Act) or to claims of culpable breach of fundamental contractual obligations through which the purpose of the contract is endangered. Otherwise, its liability for slightly negligent breach of fundamental contractual obligations is limited to the typically occurring damages which VACUUBRAND could have foreseen when the contract was concluded.

6.7 Should the customer use the delivered goods in conjunction with environmentally harmful, toxic, radioactive or otherwise hazardous materials, must notify VACUUBRAND about any such materials and decontaminate the delivered goods prior to returning them to VACUUBRAND. If the customer does not clean the goods according to the declaration of no health risk, BRAND may charge the customer for the costs required for the decontamination/cleaning and disposal of the hazardous substances arising in the process. If the device cannot be decontaminated/cleaned even by BRAND because of existing health hazards for the employees depending on the type of hazardous substances, the entire device must be disposed of as hazardous waste. The costs incurred for this shall be the responsibility of the customer.