** Designed for use with pure Butane **

Contact us for upgrade options for blended solvent or propane

The TRU series is our way of bringing quality, reliability, and accurate systems back to the market. The TRU series is all about maximizing your efficiency for every run. Equipped with a 6" x 48” spool that truly fits +5lbs of material, an IRC with a 5 micron sintered disk, ASME certified solvent tank, and to top it off it is completely fitted with Superlok compression fittings and valves. Upgrade to the 5LB TRU closed loop system today and see the USA Lab difference!

Want to customize?

Give us a call and we'll help design a custom system with you!

Process up to 30lbs of material in an 8 hour day

*Systems may have a lead time of 1-2 weeks*

| FEATURES | ||

| • The material column is 6"x48" with sight glasses to allow for viewing of up to 10lbs of milled material. | ||

| • The CRC is 6"x12" and comes with a 5 micron sintered disc and sight glasses for clear viewing of the process. | ||

| • The CRC has a built in bypass to allow easy bypass of the CRC. | ||

| • The collection is an 8"x36" and 8"x12" jacketed spool which allows for easy heating and quick cleaning. | ||

| • The 3"x 12" sieve and 10"x10" coil allow for fast and easy recovery of solvent. | ||

| • Rack mounted footprint of 74" x 39" x 66". | ||

| • High quality 1/2" Compression fittings. | ||

| • Each vessel has a 1/4" MJIC Line for connecting nitrogen lines. | ||

| • 100psi Cryogenic Pressure relief valves for safe operation. | ||

| SPECIFICATIONS | ||

| Model | 5LB-TRU | |

| Max Material | 5LB Trim | 10LB of milled material | |

| Material Column Size | 6" x 48" | |

| CRC Size | 6" x 12" 5UM | |

| Sieve Size | 3" x 12" | |

| Coil Size | 10" x 10" Bucket | |

| Solvent Tank Size | 200LB | 96lb of Butane | |

| Collection Tank Size | 8" x 48" | 37.42 Liters | |

| Foot print | 74" x 24" x 66" | |

| Weight | 550lbs | |

| PACKING LIST | ||

| Model | Quantity | |

| 200LB ASME Solvent Tank | 1 | |

| 8" x 48" Collection Tank | 1 | |

| 6"x 48" Material Column | 1 | |

| 6" x 12" CRC with 5 Micron Disc | 1 | |

| 3" x 12" Sieve | 1 | |

| 10" x 10" Condensing Coil | 1 | |

| 24" x 24" x 59" Aluminum Rack | 1 | |

|

Turnkey Packing List |

|

|

Model |

QTY |

|

TRU-10lb System |

1 |

|

UL Listed 11CFM UVP-11 Corrosion Resistant 2-Stage Vacuum Pump |

1 |

|

200°C 30L Recirculating Heater RH-30L |

1 |

|

40°C 30L Recirculating Chiller UC-30/40 |

1 |

|

Master Vapor Pump 6CFM Recovery Pump (Included in Active System) |

1 |

The USA Lab UC-30/40 is a powerful -40°C Chiller with a 30L Reservoir. This chiller is a true lab chiller than is ideal for applications involving vacuum systems, jacketed reactors, rotary evaporators, columns, solvent tanks, and even analytical instruments.

|

UC-30/40 SPECIFICATIONS |

|

|

Model |

UC-3040 |

|

Reservoir Capacity |

30L |

|

Reservoir Dimensions |

13.7" x 13.7" |

|

Temperature Range |

Room Temperature to -40°C / -40°F |

|

Power Requirements |

220-240V 60Hz 20A 1800W Single Phase |

|

Refrigerating BTUs |

4,300BTU - 13,900BTU |

|

Circulating Pump Wattage |

100W |

|

Temperature Accuracy |

+/- 0.5°C |

|

Pump Flow |

30L/Min |

|

Pump Pressure (lift/height) |

2.2bar (4m/12ft) |

|

Barb Size |

5/8" |

|

Refrigerant |

R404 |

|

Dimensions |

30.3" x 25.5" x 39.7" |

|

Weight |

180lbs |

|

UC-30/40 Packing List |

|

|

USA Lab UC-30/40 Chiller |

1 PC |

|

5/8" Insulated Tubing |

11ft |

|

5/8" barbed Valve |

1 PC |

|

PTFE Sealing Tape |

1 PC |

|

RH-30L SPECIFICATIONS |

|

•Reservoir Capacity: 30L |

|

•Reservoir Dimensions: 19" x 19" x 12" |

|

•Temperature Range: 70°C to 200°C |

|

•Power Requirements: 220-240V 50-60Hz 30A Single Phase 6-30P Plug |

|

•Heating Wattage: 5000W / 22.7A |

|

•Temperature Accuracy: +/- 0.2°C |

|

•Pump Flow w/ Water (Oil Flow Rate May Vary): 18.3L/Min |

|

•Total Pump Lift: 6m |

|

•Connection Size: 1/2" MNPT |

|

•Dimensions: 19" x 19" x 24" |

|

•Weight: 68lbs |

|

RH-30L PACKING LIST |

|

|

USA Lab RH-30L 200°C Heater |

1 pc |

|

1/2" FNPT Insulated Tubing - 6ft |

2 pcs |

|

1/2" FNPT to 1/2" Barb |

2 pcs |

|

32A Fuse |

1 pc |

|

Pre-installed 6-30P Plug |

1 pc |

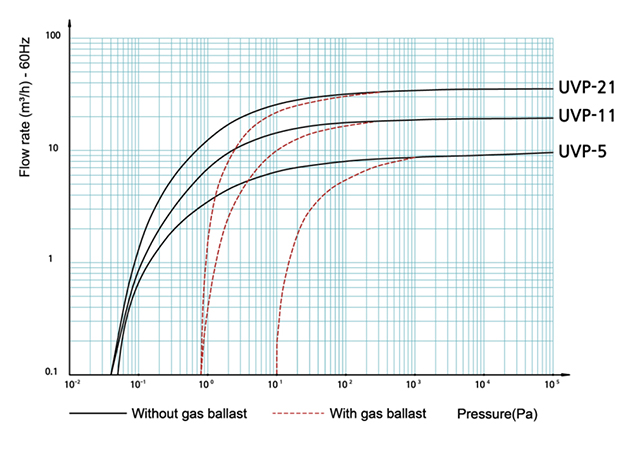

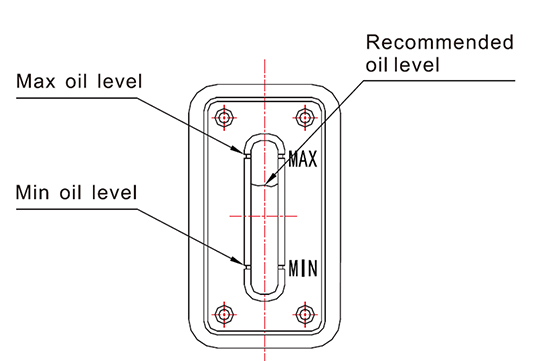

| SPECIFICATIONS | |||

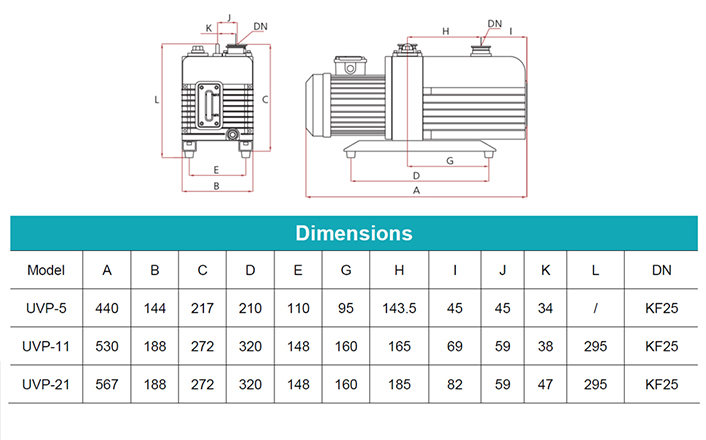

| Model | UVP-5 | UVP-11 | UVP-21 |

| Pumping Speed(60Hz) | 5.5 cfm | 11 cfm | 21 cfm |

| Ultimate total pressure gas ballast close |

4x10-2 Pa (3.0x10-4 torr) 0.3 Micron |

||

| Ultimate total pressure gas ballast open |

8x10-1 Pa (6x10-3 torr) 6 Micron |

||

| Power supply | 1 Phase (110V, 60Hz) | ||

| Power rating(kW) | 0.4 | 0.75 | 1.1 |

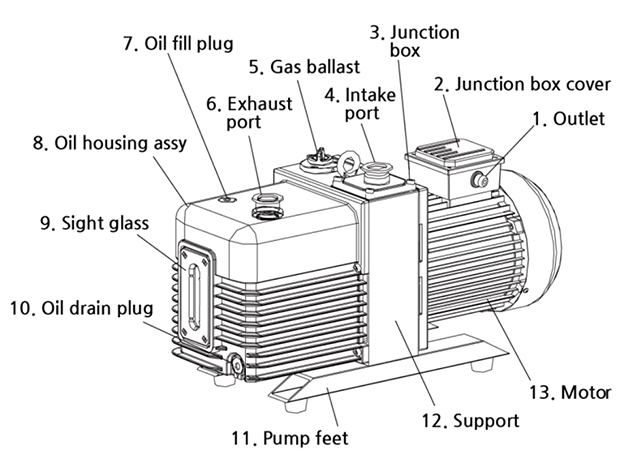

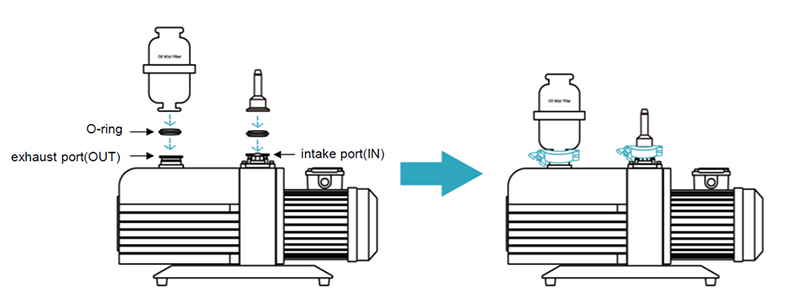

| Inlet/Exhaust Flange | KF 25 | ||

| Oil capacity(L) | 0.6~1.0 | 0.9~1.5 | 1.3~2.0 |

| Ambient temperature(℃) | 10~40℃ | ||

| Noise level(dB) | ≤56 | ≤60 | ≤60 |

| Weight(kg) | 21 | 30 | 43 |

| External Dimensions | 440x144x217MM 17.3x5.6x8.5" |

530x188x272MM 20.8x7.4x10.7" |

567x188x272MM 22.3x7.4x10.7" |

| Certification | UL | ||

| Warranty | 2 Year | ||

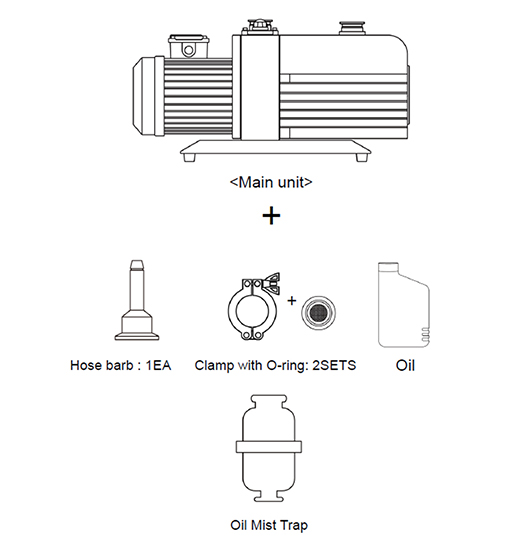

| PACKING LIST | |||

| Model | UVP-5 | UVP-11 | UVP-21 |

| Main Vacuum Pump | 1 | 1 | 1 |

| KF25 x 3/8" Barb | 1 | 1 | 1 |

| KF25 Clamp | 2 | 2 | 2 |

| KF25 O-ring | 2 | 2 | 2 |

| Oil Mist Trap | 1 | 1 | 1 |

| Quart of Oil | 1 | 1 | 1 |

| Manual | 1 | 1 | 1 |

MVP-6CFM Explosion Proof Recovery Pump

Mastor Vapor Pumps MVP-6CFM Vapor Recovery Pump can recover a staggering 1lb of vapor per minute. Each system is certified and made in the USA for superior quality. This pump is 3rd party certifiable with your system, UL listed and FDA compliant. The pump uses no oil allowing for zero contamination of your product.

You can run these pumps with 100% duty cycle, 24/7 without overheating or issue. The dual-diaphragm pump is electrically powered by an explosion-proof motor, and has a working pressure of 350psi.

Performance Factoids:

- Recover LP-Gas vapor at over 6 CFM (cubic feet per minute)

- Recover butane at up to 1 LB/Min (pounds per minute)

- Recover and re-condense butane at over 12 GPH (gallons per hour)

- Maximum pumping outlet pressure: 60 PSI (4.1 bar) continuous, 70 PSI (4.8 bar) intermittent

- Maximum pumping inlet vacuum produced: 27 InHg (0.91 bar)

- Maximum pumping speed: 190 CPM (cycles per minute)

- Pump static withstand pressure rating: MAWP 350 PSI (24 bar)

- Materials: pressure section: stainless steel; diaphragms: FKM; reed valves: stainless steel

- Optional PTFE diaphragms kit available

- Process gas temperature range: FKM -40-275F (-40-135C); PTFE +40-220F (4-104C)

- Recommended FKM replacement schedule: every 1000 hours running time

- Air temperature range for motor/gearbox operation: 32-104F(0-40C)

Pump Head Charge:

- Motor is coupled to diaphragms with patented gas pressure charged chamber

- Pumping outlet pressure runs about 10 PSI lower than the charge gas pressure level

- Non-reactive CO2 gas is used to charge the pump head

- CO2 gas is safer than air for driving the pump

- CO2 gas is non-flammable and non-explosive with LPG (should a diaphragm ever leak)

- CO2 gas regulator with gauges is provided with pump assembly

- CO2 tank is operator provided (cannot ship filled tanks) - from any welding supply store

- Pump charge gas supply: standard (#20) 5 LB tank of industrial CO2

- Typical CO2 gas usage: <0.2 SCFH (very little); estimated life of charge gas tank: 1 year

- Pump charge gas pressure range: continuous 5 to 70 PSI (1.4 to 5.5 bar); to 80 PSI intermittent

Electrical and Mechanical:

- Electric motor: explosion proof for C1D1 hazardous areas; rated Class I Gr C & D, Class II Gr F&G

- Electric motor: 1 HP, 1800 RPM, 60 Hz

- Motor option: Model MVP-6CFM-1PH: Single-phase: 115/208-230V, 13.4/6.7 FLA (full load amps)

- Motor option: Model MVP-6CFM-3PH: Three-phase: 208-230/460V, 3.3/1.65 FLA, Inverter-rated

- Pump Speed: 190 CPM (cycles per minute) at 60 Hz

- Noise: sound pressure measured 1 meter from pump: 80.5 dBa

- Porting: process inlet and outlet: 1/2" JIC-male

- Added ports for optional pressure gauges: inlet and outlet: 1/4" FNPT

- Inlet & outlet ports at ideal equipment connections heights 46" and 41" above floor

- Size: 17.0" x 19.9" x 46" tall; minimum use of valuable floor space

- Weight: 182.5 lb (82.8 kg)

Documents:

For Technical Support, Questions, or Other Issues Please Email or Call Us!