-

USA Lab Pharmaceutical Freeze dryer - 3 shelves | <-76°C

USA LabUSA-PFD-3Sale $14,200.00RetailThe USA Lab Pharmecutifcal Freeze Dryer is not just a regular lab freeze dryer. This unit is equipped with a LCD Touchscreen Display and customizable recipe control. The controller allows you -

USA LAB Hat

USA LabUSA-HATSale $10.00Retail $14.99Our USA Lab Hat is a one size fits all hat. It's also easy and comfortable way to rep your favorite lab equipment company! -

USA Lab Acetone

USA LabSale $18.00 - $845.00RetailACETONE | USA Lab *Hazmat fee applied at checkout* -

USA Lab Dichloromethane Lab Grade 99.9%

USA LabDCM-Sale $25.00 - $1,175.00RetailDichloromethane (DCM) - USA Lab *Hazmat fee applied at checkout* Dropship Item Lab Grade -

USA LAB Trucker Hat

USA LabUSA-THSale $10.00Retail $14.99The USA Lab Hat is a easy and comfortable way to rep your favorite lab equipment company!

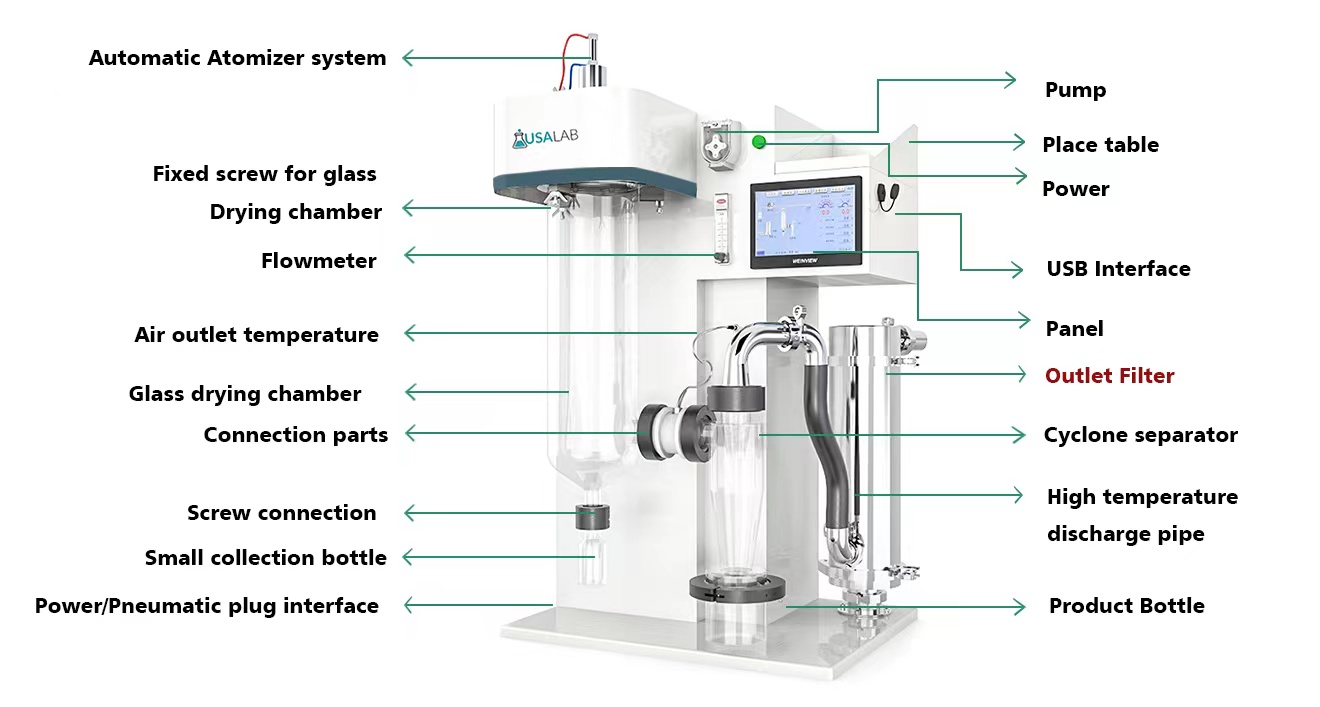

Description

The USA Lab Spray Dryer can be used to dry aqueous solutions and suspensions.It is suitable for experiments and production where the product is required to be uniform in powder form.

* No organic solvents, only aqueous solutions *

Spray drying is accomplished by dissolving, emulsifying or dispersing the core substance in a solvent or in a solution of carrier material. The material is then atomized and sprayed into the drying

chamber where a hot stream of drying gas helps evaporate the solvent to produce dry solid particles. These particles are further separated from the gas stream and collected using centrifugal

forces with a cyclone

Common uses for the mini spray dryer include: pharmaceuticals, dyes, food, beverages, pigments, milk etc.

This instrument is suitable for the laboratory to directly convert liquid materials into micro powders, without the need to filter, concentrate and crush the materials before drying. The Spray Dryer has broad-spectrum applicability to all solutions such as emulsions and suspensions along with a pneumatic atomization spray system.

** Notice **

NOT Compaible With 208V Power Input

(Acceptable range: 219V - 253V)

NOT Compaible With 208V Power Input

(Acceptable range: 219V - 253V)

|

Specification |

Details |

|

Power consumption |

3.6KW | 16.4A | NEMA 6-20 plug |

|

Voltage |

220V 60HZ |

|

Evaporation capacity |

2000ml/h @ 70% Yield Maximum |

|

Dry air flow |

70m3/h(MAX 600m3/h) | 1000Pa |

|

Fan power |

220V @ 400W | Variable Flow |

|

Inlet air temperature |

30-250℃ ±1℃ |

|

Outlet temperature |

30-120℃ ±1℃ |

|

Heating capacity |

3.0KW |

|

Heating control |

PT-100 Sensor | PID | ±1℃ |

|

Air compressor |

250W | MAX 4.2m3/H | 29 - 116 psi |

|

Spray system |

Pneumatic Atomization |

|

Average drying time |

1.0-1.5s |

|

Automatic unblocking function |

Automatic nozzle clearing with adjustable frequency |

|

Control System |

Siemens S7-200smartPLC w/ 7 inch touch screen |

|

Glass components |

3.3 Borosilicate glass |

|

Nozzle/heater/cyclone separator |

316L stainless steel |

|

Seals |

PTFE |

|

Product feed pipe |

Silicone Rubber |

|

Exhaust pipe |

Polyurethane |

|

Dimensions |

650×570×900mm | 25.6 x 22.5 x 35.43" |

|

Weight |

60KG | 132lbs |

|

Manual |

|

|

Air Compressor |

Not Included |

*Air Compressor & Filter Not Included*

Air Compressor & Filter Recommendation

For Technical Support, Questions, or Other Issues Please Email or Call Us!