No expense has been spared with this reactor turnkey system, yet we crush the market on pricing to provide great value at a low cost. Our reactor turnkey systems are the best value on the market and each one comes with fantastic customer service, local product support and a 1-year warranty.

Bring your lab to the next level and get started with a USA Lab single jacketed reactor turnkey system today!

NOT Compaible With 208V Power Input

(Acceptable range: 219V - 253V, excluding vacuum pump and reactor)

*NOTE: When paired with a reactor, fluid requirement is nearly 9 gallons*

ETL only applies to reactor

-THIS SYSTEM INCLUDES-

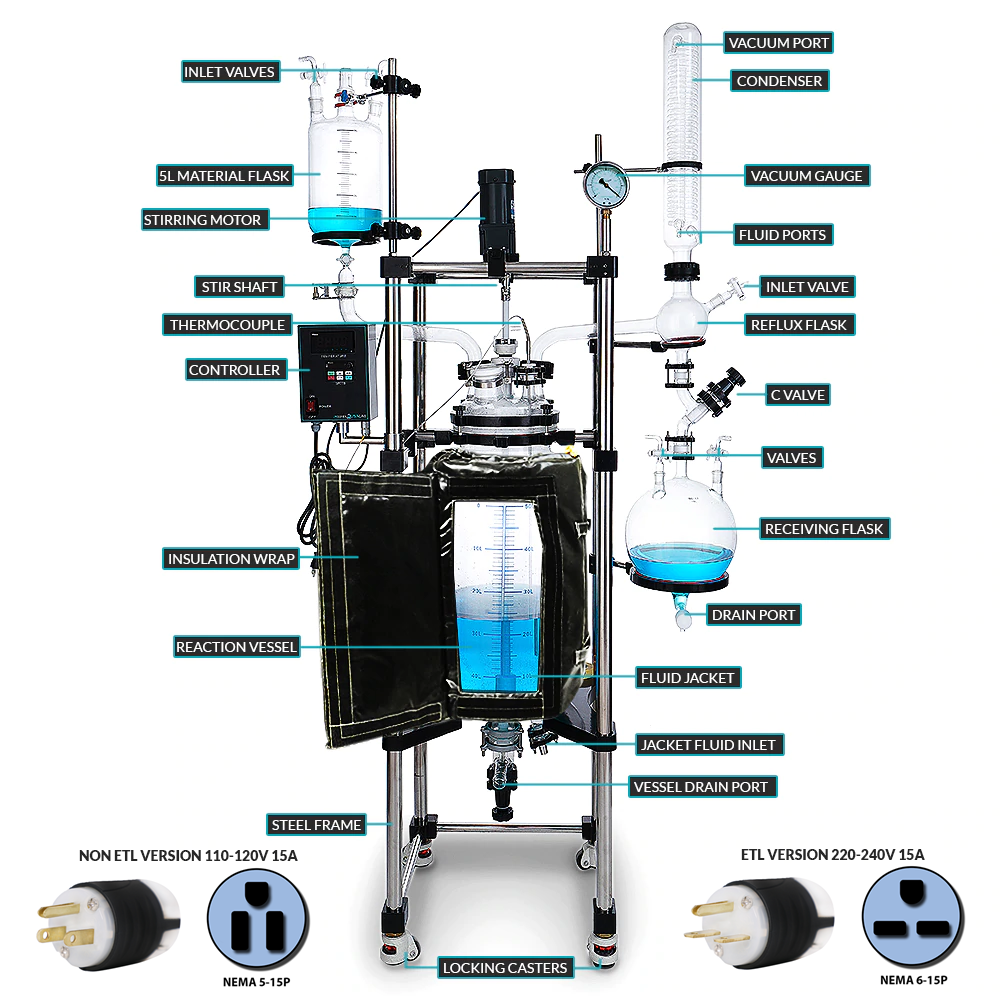

•1x: USA Lab 50L Single Jacketed Reactor JR-50

•1x: USA Lab 12L -40°C to 200°C Heater Chiller UHC-50/40

•1x: USA Lab 50L -30°C Chiller UC-50/30

•1x: Vacuubrand MD 4C NT 2.2CFM Chemistry Diaphragm Pump

•3x: 5 Gallon Buckets of Propylene Glycol

-REACTOR INFORMATION-

|

JR REACTOR FEATURES |

|||||

|

• ETL to UL and CSA Standards (Reactor only) >INTERTEK CSA CERTIFICATION< >INTERTEK UL CERTIFICATION< |

|||||

|

• All glassware is made from high grade borosilicate glass that is durable and resistant. |

|||||

|

• Wide range of temperature operations -80°C to 210°C |

|||||

|

• All seals are PTFE to increase durability and longevity. PTFE is resistant to a large portion of solvents and chemicals. |

|||||

|

• Rugged, High RPM stirring motor for superior stirring power. |

|||||

|

• Large condensing area for faster condensing. |

|||||

|

• Durable stainless steel support frame with casters. |

|||||

|

• 1 Year warranty with US base parts and support. |

|||||

|

JR REACTOR SPECIFICATIONS |

|||||

|

Model |

JR5 |

JR10 |

JR20 |

JR50 (INCLUDED) |

JR100 |

|

Vessel Capacity |

5L / 1.32Gal |

10L / 2.6Gal |

20L / 5.28Gal |

50L / 13.20Gal |

100L / 26.41Gal |

|

Material Flask Capacity |

1L / 0.26Gal |

2L / 0.52Gal |

5L / 1.32Gal |

5L / 1.32Gal |

5L / 1.32Gal |

|

Receiving Flask Capacity |

Not included |

5L / 1.32Gal |

5L / 1.32Gal |

10L / 2.6Gal |

10L / 2.6Gal |

|

Fluid Jacket Capacity |

0.8L / 0.21Gal |

8L / 2.11Gal |

9L / 2.37Gal |

16L / 4.22Gal |

25L / 6.60Gal |

|

Glass Material |

GG-17 Borosilicate Glass | Thickness: 6.5mm ±0.5mm |

||||

|

Rotary Speed |

0-450RPM |

||||

|

Glass Temperature Range |

-80°C to 250°C / -112°F to 482 |

||||

|

Power Requirements |

230V 60Hz 15A 1p |

||||

|

Stirrer Wattage |

120W |

120W |

120W |

120W |

200W |

|

Lowest Vacuum Level |

0.0033 Mpa | 25 Torr | 25,000 Micron |

||||

|

Speed Regulation |

Digital Step-Less |

||||

|

Condenser and Feed Valve Barbs |

10MM - 3/8" |

||||

|

Bottom Drain Port |

35MM - 1 3/8" |

||||

|

Receiving Flask Barb |

16MM - 5/8" |

||||

|

Jacket Pressure |

Maximum 29 psi - Nominal 25 psi |

||||

|

Fluid Connection |

16MM - 5/8" barb or 1/2" NPT (100L: 5/8 Barb or 3/4" MNPT) |

||||

|

Certification |

ETL to UL and CSA Standards |

||||

|

External Dimensions LxWxH |

16 x 18 x 68" |

20.4 x 20.4 x 70" |

39 x 20.4 x 79" |

41 x 23 x 90" |

48 x 34 x 102" |

|

Weight |

75 lbs |

149 lbs |

176 lbs |

205 lbs |

275 lbs |

|

JR REACTOR PACKING LIST |

|||||

|

Model |

Quantity |

||||

|

Vessel with Rack (Pre-assembled) |

1 |

||||

|

Main Condenser |

1 |

||||

|

Material Flask |

1 |

||||

|

Receiving Flask |

1 |

||||

|

Reflux Flask |

1 |

||||

|

C Clamp Valve |

1 |

||||

|

Feed Ports |

6 Sets |

||||

|

Stopper |

1 |

||||

|

Clamp for Material Flask |

1 |

||||

|

Strap for Condenser |

1 Set |

||||

|

Sealing Screw / Flange |

3 Sets |

||||

|

Fluid Line Sealing Clamp / Flange |

2 sets |

||||

|

Control Box |

1 |

||||

|

Vacuum Gauge |

1 |

||||

|

Support Rings |

2 |

||||

|

Stirring Motor w/ Paddle |

1 |

||||

|

Temperature Probe |

1 |

||||

|

Liquid 5/8" Connections |

2 |

||||

|

Metal Clamp |

2 |

||||

|

Insulation Wrap |

1 |

||||

|

DuPont Molykote High Vacuum Grease |

1 |

||||

|

Vacuum Hose |

10 ft. |

||||

|

JR REACTOR LID SPECIFICATIONS |

|||||

|

Model |

JR-5L |

JR-10L |

JR-20L |

JR-50L |

JR-100L |

|

Left Port |

29mm Joint |

40mm Joint |

50mm Ball Joint |

50mm Ball Joint |

50mm Ball Joint |

|

Right Port |

35mm Ball Joint |

50mm Ball Joint |

50mm Ball Joint |

50mm Ball Joint |

50mm Ball Joint |

|

Rear Port |

24mm Joint |

34mm Joint |

34mm Joint |

34mm Joint |

34mm Joint |

|

Stirring Port |

50mm Flange Port |

50mm Flange Port |

50mm Flange Port |

50mm Flange Port |

60mm Flange Port |

|

Front Port 1 |

N/A |

80mm with PTFE Lid |

80mm with PTFE Lid |

80mm with PTFE Lid |

80mm with PTFE Lid |

|

Front Port 2 |

24mm Joint |

50mm Flange Port |

50mm Flange Port |

50mm Flange Port |

50mm Flange Port |

|

Explosion Proof Motor Specifications |

||||||

|

Model |

JR-5L |

JR-10L |

JR-20L |

JR-50L |

JR-100L |

JR-150L |

|

Wattage / HP |

90W | 1/8 HP |

180W | 1/4 HP |

370W | 1/2HP |

|||

|

Current(A) |

0.7A |

1.12A |

1.94A |

|||

|

RPM |

0-1400rpm |

|||||

|

Power |

240V 60Hz |

|||||

|

Pneumatic Motor Specifications |

||||||

|

Wattage / HP |

560W | 3/4 HP |

|||||

|

RPM |

0-650rpm |

|||||

|

Air Consumption |

504L/min |

|||||

-HEATER CHILLER INFORMATION-

|

UHC HEATER CHILLER FEATURES |

|||

|

• Enclosed closed loop system allowing safer operation and higher circulating temperatures. |

|||

|

• High quality UL Listed compressors. |

|||

|

• Wide range of temperature operations -40°C to 200°C |

|||

|

• Easily accessible control panels for repairs and cleaning. |

|||

|

• 1 Year warranty with US base parts and support. |

|||

|

UHC HEATER CHILLER SPECIFICATIONS |

|||

|

Model |

UHC-10/40 |

UHC-20/40 |

UHC-50/40(INCLUDED) |

|

Reservoir Capacity |

6L / 1.58Gal |

6L / 1.58Gal |

12L / 3.17Gal |

|

Temperature Range |

Room to -40° to 200°C |

||

|

Power Requirements |

220-240V 60Hz 20A 3000W 1P 6-20Plug |

220-240V 60Hz 30A 6000W 1P 6-30Plug |

220-240V 60Hz 40A 6000W 1P Hard Wired |

|

Heating Wattage |

3kW |

3kW |

6kW |

|

Refrigerating Wattage |

2kW |

2kW |

2kW |

|

Circulating Pump Wattage |

100W |

100W |

280W |

|

Temperature Accuracy |

+/- 2°C |

||

|

Pump Flow |

18L/Min |

18L/Min |

35L/Min |

|

Pump Pressure |

4Kpa |

||

|

Connection Size |

3/4" |

||

|

External Dimensions LxWxH |

25" x 22" x 42" |

25" x 22" x 42" |

28" x 26" x 44" |

|

Weight |

187lbs |

197lbs |

264lbs |

|

UHC HEATER CHILLER PACKING LIST |

|||

|

Model |

Quantity |

||

|

UHC Heater Chiller |

1 |

||

|

3/4" Insulated Tubing - 6ft |

2 |

||

|

3/4" Valve |

1 |

||

|

3/4" NPT Hex |

1 |

||

|

PTFE Sealing Tape |

1 |

||

|

Manual |

1 |

||

-CHILLER INFORMATION-

The USA Lab UC Chiller is a powerful Chiller with a large Reservoir. This chiller is a true lab chiller than is ideal for applications involving vacuum systems, jacketed reactors, rotary evaporators, columns, solvent tanks, and even analytical instruments.

The USA Lab UC chillers offer unbeatable performance, ease of use and high reliability. These units keep quiet despite having a powerful pump allowing for constant flow rates to match the needs of demanding applications.

|

UC CHILLER FEATURES |

|||||||

|

• Powerful chilling capacities and high BTU range. |

|||||||

|

• High quality UL Listed compressors. |

|||||||

|

• Wide range of temperature operations. |

|||||||

|

• Eco-friendly R404 refrigerant. |

|||||||

|

• 12ft of tubing included. |

|||||||

|

• 1 Year warranty with US base parts and support. |

|||||||

|

UC CHILLER SPECIFICATIONS |

|||||||

|

Model |

UC-5/10 |

UC-20/20 |

UC-20/40 |

UC-30/30 |

UC-30/40 |

UC-30/80 |

UC-50/30(INCLUDED) |

|

Reservoir Capacity |

5L / 1.32Gal |

20L / 5.28Gal |

30L / 7.92Gal |

50L / 13.20Gal |

|||

|

Temperature Range |

Room to |

Room to |

Room to |

Room to |

Room to |

Room to |

Room to |

|

Power Requirements |

110-120V 60Hz 20A 1800W 1P |

220-240V 60Hz 20A 1800W 1P |

220-240V 60Hz 30A 5250W 1P |

220-240V 60Hz 20A 1800W 1P |

|||

|

Controller Type |

Digital |

PLC |

Digital |

||||

|

Refrigerating BTU |

4,500 - 1,000BTU |

3,000 - 10,500BTU |

3,300 - 12,400BTU |

4,000 - 13,500BTU |

4,300 - 13,900BTU |

1,450 - 16,000BTU |

12,000 - 25,500BTU |

|

Circulating Pump Wattage |

100W |

||||||

|

Temperature Accuracy |

+/- 0.5°C |

||||||

|

Pump Flow |

30L/Min |

||||||

|

Pump Pressure |

2.2bar |

||||||

|

Connection Size |

5/8" |

||||||

|

Refrigerant |

R404 |

||||||

|

External Dimensions LxWxH |

29" x 14" x 29" |

25" x 21" x 43" |

25" x 21" x 43" |

31" x 26" x 40" |

31" x 26" x 40" |

39" x 32" x 48" |

31" x 26" x 46" |

|

Weight |

100lbs |

154lbs |

164lbs |

171lbs |

180lbs |

473lbs |

174lbs |

|

UC CHILLER PACKING LIST |

|||||||

|

Model |

Quantity |

||||||

|

UC Chiller |

1 |

||||||

|

5/8" Insulated Tubing - 6ft |

2 |

||||||

|

5/8" Valve |

1 |

||||||

|

PTFE Sealing Tape |

1 |

||||||

|

Manual |

1 |

||||||

-VACUUM PUMP INFORMATION-

MD 4C NT

Three-Stage Chemistry-Design Diaphragm Pumps are an excellent solution for continuous, oil-free pumping of corrosive gases and vapors and meet even challenging requirements. The three-stage design provides the advantageous combination of high pumping speed and very low ultimate vacuum. All parts of the MD 4C NT in contact with pumped media are made of chemically resistant fluoroplastics. Well-proven PTFE sandwich diaphragms provide increased reliability and extended operating life. Due to the gas ballast valve and its very good ultimate vacuum (even with gas ballast) the MD 4C NT is also suitable for pumping condensable vapors of high-boiling solvents. The NT-series features further improved performance data, easy service and superior vapor tolerance.

Performance Features

- Outstanding chemical resistance and superior vapor tolerance

- Exceptionally high performance even at low vacuum

- Excellent ultimate vacuum even with gas ballast

- Whisper quiet and very low vibration

- Long diaphragm life, maintenance-free drive system

|

Technical data |

MD 4C NT |

|

Number Of Heads / Stages |

4 / 3 |

|

Max. Pumping Speed At 50/60 Hz |

3.4 / 3.8 m3/h |

|

Max. Pumping Speed At 50/60 Hz |

2.0 / 2.2 cfm |

|

Ultimate Vacuum (Abs.) |

1.5 / 1.1 mbar/torr |

|

Ultim. Vac. (Abs.) With Gas Ballast |

3 / 2.2 mbar/torr |

|

Ambient Temperature Range (Operation) |

(10°C) - (40°C) |

|

Ambient Temperature Range (Storage) |

(-10°C) - (60°C) |

|

Max. Back Pressure (Abs.) |

1.1 bar |

|

Inlet Connection |

Hose nozzle DN 8-10 mm |

|

Outlet Connection |

Hose nozzle DN 8-10 mm |

|

Rated Motor Power |

0.25 kW |

|

Rated Motor Speed At 50/60 Hz |

1500/1800 min-1 |

|

Degree Of Protection |

IP 40 |

|

Dimensions (L X W X H) |

325 x 243 x 198 mm |

|

Weight |

14.3kg |

|

Noise Level At 50 Hz, Typ. |

45 Dba |

|

NRTL Certification |

Canada and the USA |

|

Atex Conformity (Only 230V) |

II 3/- G IIC T3 X Internal Atm. only |

|

Items Supplied |

Pump completely mounted, ready for use, with manual |

|

Accessories |

Rubber Vacuum Tubing DN 8 mm (20686001) |

-

-

MD 4C NT - Pumping Speed Graph at 60 Hz

-

MD 4C NT - Pump Down Graph at 60 Hz (10L volume)

-

-Technical data are subject to change without notice-

MD 4C NT - Dimension Sheet