Best Practices for Using Vacuum Oven BHO in Extraction Processes

Getting the best results from a vacuum oven in butane hash oil (BHO) extraction involves a deep understanding of how each element (temperature, pressure, and time) affects the final extract. Every detail, from maintaining the right temperature to knowing the perfect vacuum pressure, makes a huge difference. Fine-tuning these factors directly influences the efficacy of solvent removal.

Why Fine-Tuning Matters

Even seasoned BHO extractors know that consistent, high-quality results depend on precision at every step of the process. While vacuum ovens are designed for the efficient removal of unwanted substances in a low-pressure environment, small variations in temperature, pressure, or setup can have a big impact on the end product.

Dialing in the right parameters for your vacuum oven preserves the beneficial terpenes and cannabinoids that give your extracts their potency, flavor, and aroma. Additionally, maintaining proper equipment functionality, like ensuring airtight seals and even heat distribution, prevents costly mistakes, wasted material, and safety risks.

By refining your approach and adopting proven best practices, you can fully take advantage of your vacuum oven's capabilities. This allows you to produce purer extracts while optimizing efficiency and consistency across batches.

Set Optimal Temperatures

The ideal temperature range within the vacuum chamber is typically between 90ºF and 115ºF. This range balances the need to effectively evaporate solvents while preserving the delicate terpenes that contribute to the flavor and aroma of the extract.

Operating at the lower end of this spectrum (90ºF to 100ºF) helps preserve terpenes, which are volatile and can degrade or evaporate at higher temperatures. Maintaining these low temperatures is recommended when aroma and flavor quality is a priority.

As the purging process progresses, some extractors may slightly increase the temperature within the 101ºF to 115ºF range to expedite the removal of residual solvents. The controlled increase helps to enhance the efficiency while still avoiding excessive heat that could degrade valuable compounds.

Monitor Consistently

Use high-quality, accurate thermometers to monitor the temperature effectively. These instruments should ideally be calibrated regularly to maintain their precision.

Digital thermometers with remote monitoring capabilities allow for real-time tracking and adjustments without needing to open the oven, which could disrupt the vacuum environment and solvents' ability to off-gas efficiently.

Throughout the extraction process, regularly check the internal temperature at predetermined intervals depending on the length of the extraction cycle. For shorter cycles, checking every 15 to 30 minutes might be necessary, while for longer cycles, hourly checks could suffice.

Keeping a log of temperature readings during the extraction process can help identify any patterns or inconsistencies that might affect the quality of the extract. This data is valuable for troubleshooting and refining future extractions.

If temperatures deviate from the desired range, immediate adjustments should be made, which could involve tweaking the heat settings or inspecting the vacuum-drying oven for any operational issues that could be affecting its performance.

Ideal Pressure Settings

The vacuum pressure must be significantly lower than atmospheric pressure to reduce the boiling point of butane, allowing it to evaporate at lower temperatures that are gentle on the plant’s compounds. However, too high a vacuum can lead to the rapid boiling of butane, which might disturb the material matrix and potentially lead to the loss of terpenes.

The "sweet spot" for vacuum levels can vary significantly depending on several factors, such as the type of material being processed, the consistency of the extract, and the specific characteristics of the vacuum oven used. Generally, vacuum pressures are measured in Torr or mmHg, with many extraction processes operating in the range of 100 to 500 microns (0.1 to 0.5 Torr).

Start with the manufacturer’s recommended settings and adjust from there. It may be necessary to experiment with different pressures in initial runs to observe how the extract and solvent behave. Note these observations and make adjustments accordingly.

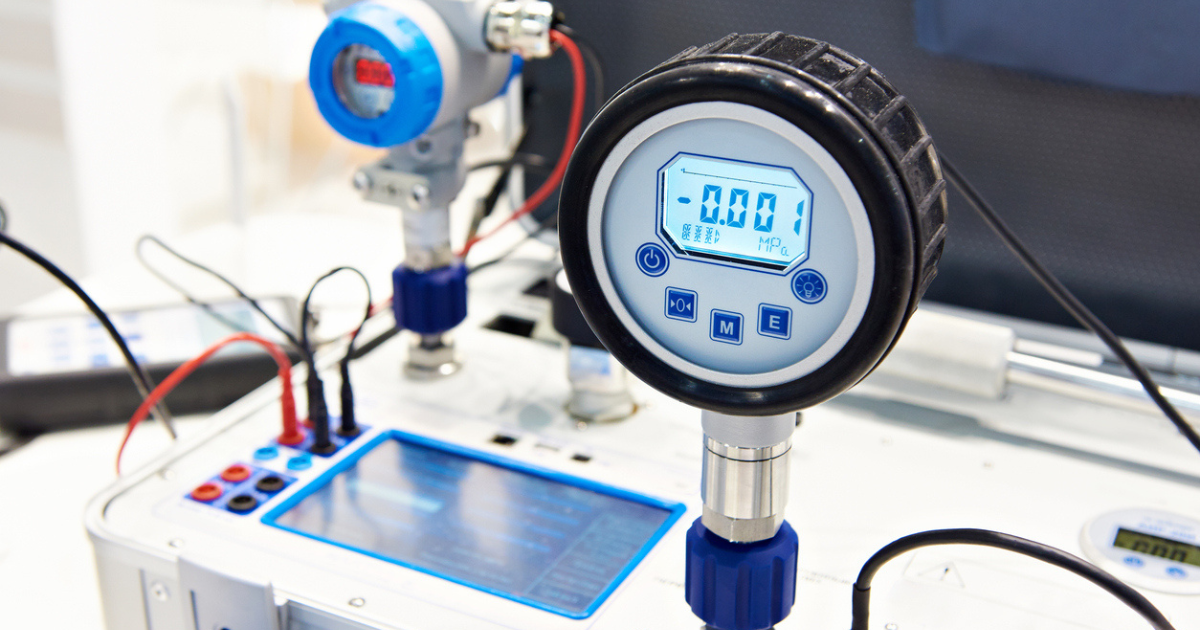

Use a reliable vacuum gauge to continuously monitor the pressure during the extraction process. Digital gauges can provide precise readings and should be calibrated regularly to maintain accuracy. If the pressure deviates from the optimal range, adjustments should be made promptly to stabilize it.

Keep detailed records of the pressure settings used for each batch along with the outcomes. This documentation can be invaluable for replicating successful batches and troubleshooting those that did not meet expectations.

Leak Prevention

Inspect your vacuum oven regularly for any signs of wear and tear that could lead to leaks. Focus on areas such as door seals, gaskets, connection points, and the vacuum pump itself. These components can degrade over time and may need replacement or adjustment to maintain a tight seal.

Invest in high-quality, durable seals and gaskets that are resistant to the temperatures and chemicals involved in BHO extraction. These components must be specifically designed for vacuum applications. Standard parts may not provide an adequate seal under low-pressure conditions.

If a leak is detected, it should be addressed immediately to prevent any disruption to the extraction process. Small leaks can often be repaired temporarily with vacuum-rated tape or sealant, but these should only be considered short-term solutions until proper repairs can be made.

After any maintenance or before starting a new extraction batch, perform a leak test by applying a deep vacuum to the system and then observing if the pressure holds without the vacuum pump running. Another method is to use a leak detector, which can pinpoint even minor leaks more accurately.

Keep a log of all maintenance activities, including inspections, repairs, and replacements. This record helps track the lifespan of components and plan preventive maintenance, which can improve the overall reliability of your equipment.

Even Distribution

Spreading the extract as thinly and evenly as possible across parchment-lined trays maximizes the surface area exposed to heat and vacuum for a more uniform heat absorption and solvent evaporation. Thick or uneven layers can result in pockets where solvent might remain trapped, leading to inconsistent quality in the extract.

Lining trays with parchment paper prevents the extract from sticking to them, which not only helps with even heating but also simplifies the process of removing the finished product. Make sure that the parchment paper is cut to fit the tray exactly and is flat without any creases or folds.

Additionally, don’t overload the trays. While it might be tempting to process larger batches at once, overloading can cause overlap or thicker layers of extract, which can impede heat penetration and solvent removal. Processing smaller batches provides more control and consistency.

If your vacuum oven has multiple shelves, rotating the trays between shelves during the extraction process can help achieve excellent temperature uniformity and solvent removal. This is because different parts of the oven might have slight temperature variations.

Throughout the extraction process, regularly check the trays to observe the melting and bubbling patterns. This can indicate whether the extract is heating evenly or if adjustments need to be made, such as re-spreading the extract or adjusting tray positions.

Avoid Overcrowding

When the oven is crowded, the trays are likely to block or disrupt the flow of heat within the chamber resulting in uneven heating, where some areas of the material may not receive enough heat to fully purge the solvents.

Adequate space allows for better airflow and heat distribution, which promotes efficient solvent removal. Crowded conditions can trap solvents within the material, leading to batches that are inconsistent in quality and potentially unsafe due to residual solvents.

Optimize batch sizes to fit your extraction equipment and space trays adequately. This setup promotes even heat distribution and air circulation

Monitor the extract's temperature and consistency regularly, adjusting tray placement for even heating. Experiment with batch sizes and maintain detailed records to optimize efficiency and quality in your vacuum oven.

Timely Purging

The appropriate length of time needed to purge solvents can vary significantly based on several factors, including the amount of material being processed, the specific type of vacuum oven used, and the initial concentration of solvents.

Start with the manufacturer’s recommendations for purge times based on your oven model and adjust from there. For many setups, initial purging might begin with shorter intervals, with the process monitored closely to gauge effectiveness.

Observe the extract's behavior throughout the purging process. Look for signs that solvent is still being released, such as bubbling or changes in the extract's appearance. Adjust the duration based on these observations so that all solvent is removed without over-purging, which could degrade valuable compounds.

Using analytical tools like residual solvent analyzers can provide precise measurements and help determine when the purge is complete. This is especially useful in commercial operations where consistency and compliance with safety standards are critical.

Routine Cleaning

Immediately after each extraction session, ensure that the oven and trays are cleaned to avoid residue hardening. This can become more difficult to remove over time and may require harsher chemicals to clean.

Use solvents and cleaners that are safe and effective for use with your vacuum oven. Isopropyl alcohol, for example, is commonly used for its effectiveness in dissolving oily residues and its rapid evaporation rate. The cleaner used should be compatible with the materials of your oven and trays to avoid damage.

Wipe down all surfaces inside the oven, including the window, if applicable, and the door seal. Use soft, non-abrasive cloths or sponges to avoid scratching any surfaces. For any stubborn residues, a gentle scrub with a brush specifically designed for non-stick surfaces can be effective.

After cleaning, ensure that all components are thoroughly dried before reassembling or storing the oven to prevent the onset of rust or corrosion on metal parts and maintain the integrity of any seals or gaskets.

While cleaning, inspect the condition of the interior surfaces, trays, seals, and gaskets. Check for any signs of wear, tearing, or degradation, and replace these components as necessary to maintain a good seal and overall functionality.

Keep track of each cleaning session along with any observations or issues noted during the process to track the maintenance schedule and identify when parts are due for replacement or when a more thorough cleaning might be needed.

Use Proper Ventilation

The area where the vacuum drying ovens operate should be equipped with an effective ventilation system that can evacuate potentially hazardous fumes. This could include fume hoods, exhaust fans, or air filtration systems designed to cope with solvent vapors.

Regularly inspect and maintain your ventilation equipment for optimal functioning. Check for blockages to keep filters clean and that all fans and hoods are operating at full capacity.

Comply with local safety regulations regarding ventilation in environments where flammable vapors are present. This might include specific requirements for air changes per hour (ACH) or the type of ventilation system installed.

Arrange your workspace to maximize the efficiency of the ventilation system. Vacuum ovens should be placed where fumes can be directly captured and evacuated by the ventilation system without accumulating or spreading to other areas.

Consider using air quality monitors to detect the presence of volatile organic compounds (VOCs) in the air. This can provide a real-time assessment of air safety and help determine if additional ventilation measures are needed.

Regular Calibration

Sensors and gauges can drift over time due to wear and environmental factors, leading to inaccurate readings affecting the control of temperature and pressure within the oven. This impacts the efficiency of the extraction and the quality of the extract.

Establish a routine calibration schedule based on the manufacturer’s recommendations and the frequency of use. For high-usage environments, more frequent calibration may be necessary to ensure continued accuracy.

Use professional calibration services for critical instruments. These services use certified standards to calibrate equipment, assuring that your sensors and gauges meet required accuracy levels.

In addition to professional services, conduct regular on-site checks using calibration kits or reference instruments. This is particularly useful for quick verifications between scheduled professional calibrations.

Optimizing Your Vacuum Oven

Effectively using a vacuum oven for BHO extraction requires precise control and diligent practice. Setting optimal temperatures and pressures while closely monitoring each phase maintains the quality and safety of your extracts. Adhering to these best practices maximizes the efficiency of your operations and extends the lifespan of your equipment.