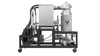

Recovery Skid ( 450L HR) | USA Lab

The Beaker & Wrench Solvent Recovery System is a more energy-efficient machine with a smaller footprint that achieves both higher ease-of-use for busy professionals and purer output for the end-user.

The new Solvent Recovery uses a patent pending closed cycle heat pump technology to reduce energy consumption by >80%. Meaning that you can recover 5x the solvent for the same amount of power with near 0% residual solvent in the oil. In addition to the energy factor of the machine, Beaker & Wrench have equipped the Solvent recovery with an Internet enabled computer control interface that is easy and efficient to use. This control panel allows the user to fully control the Solvent Recovery form a single interface or even remotely.

In stark contrast to the energy-heavy, extremely large machinery available elsewhere in the marketplace, Beaker & Wrench again has produced a superior product at a fraction of the normal footprint. Using the Beaker & Wrench Solvent Recovery System, your lab can reliably recover 5x the solvent using the same amount of power—with near 0% residual solvent left behind in the oil.

|

Component |

Specifications |

|

Solvent Recovery Skid |

76” L x 31” W x 77” H |

|

Electrical and Controls Cabinet |

30” W x 84” H x 33” L |

|

Cooling Tower |

63” L x 33” W x 69” H |

|

Electrical Requirements |

240VAC 3 Phase 60 Hz, 120 Amps |

|

Incoming Power Cable |

10ft 4 Conductor with Ground 00 AWG Cable, Termination by Customer |

|

Power/Communication to Cooling Tower |

30ft Cable Length, Termination by Customer |

|

Input Voltage |

240VAC 3 Phase 60 Hz |

|

External Circuit Breaker |

150 amp |

|

Nominal Current |

110 amps |

|

Control Interface |

Custom 10” Cabinet Mounted Touchscreen |

|

Cooling Skid |

6” Castors w/Brakes |

|

Recovery Rate |

(Assuming 90% Solvent to Oil Mixture) Ethanol: Up to 450 LPH 5% Residual Solvent, Methanol: 600 LPH 2% Residual Solvent |

For Technical Support, Questions, or Other Issues Please Email or Call Us!